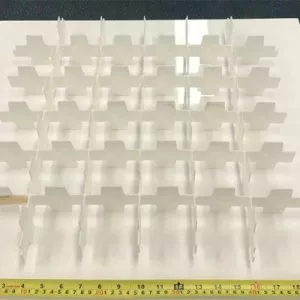

RC 301 crate washer

The RC 301 crate and multipurpose washer (previously known as the VX 301 model) has a capacity of approx. 300 crates/hour. These crate washers are ideal for medium-large sized farms, facilities and establishments where crate washing is required.

Several options are available to provide the best fit into the wash area and minimize the need of effort and labour. Rhima can quote and supply robots to load/unload and stack/destack at each end. The RC 301 model can be built for left or right loading.

This unit has a hot (65°C) chemical wash and then a fresh water final rinse at min.82°C to comply with HACCP guidelines. Water consumption is minimal and water is recycled several times within the machine.

Optional Items:

- Heat Recovery units which supply the machine with cold water (inlet water temperature between 8°C and 15°C) and significantly save energy at the same time. The steam produced by the machine operation (otherwise lost in the room) is recovered and led through the heat exchanger (air – water). The energy of the steam is used to preheat up to 45°C the inlet water with a consequent reduction of energy consumption.

- Detergent Dispenser which means that chemicals are able to be connected to the machine and are automatically dosed and injected into the wash cycle of the machine

- Blowers

Benefits

- Insulated doors which helps to maintain a constant temperature in the washing chamber which in turn allows for a reduction of power consumptions for the boiler heating elements.

- CPF which is a device that allows for user to easily adjust the water pressure in the prewash or wash phase depending on each users needs,

- AIS 304 and 316 stainless steel which allows protection from aggressive cleaning agents and salty water.

- The standard machines are electrically heated, steam is an option.

- Wide inspection doors give full access to the wash zone.